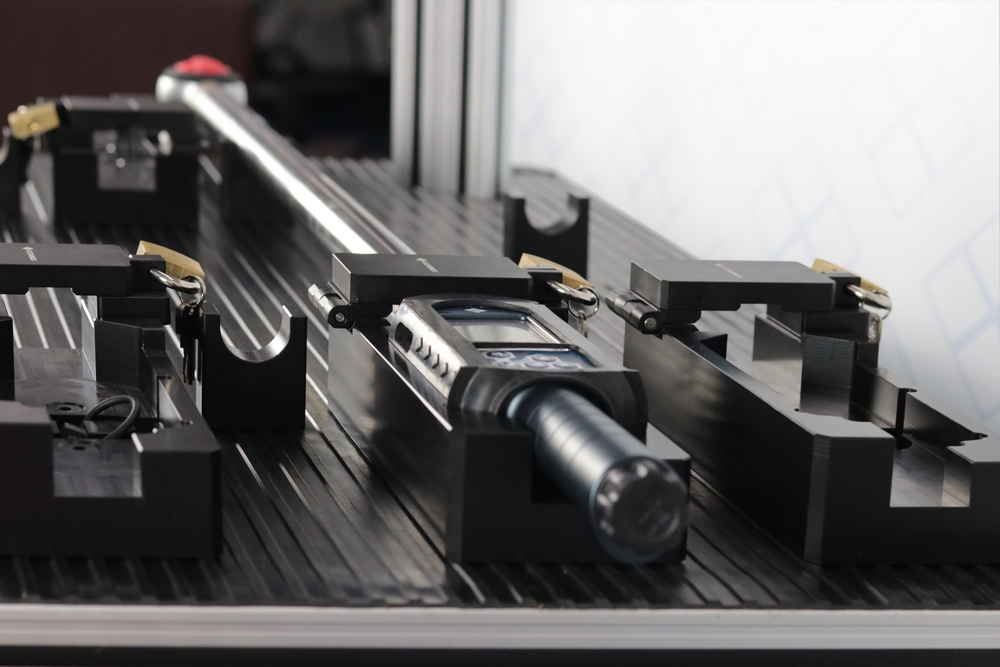

Rework Workbench – M.Shimizu

Designed to be used as a rework station (outside the assembly lines), batch production, as a backup tool on the production line, training station or according to the customer’s needs, who needs mobility, quality and traceability.

* Autonomy of up to 8 hours, with rechargeable batteries.

* All-in-one industrial computer, optional with touch screen or additional screen.

* It adds elements of mobility, hardware and customizable software.

* Supports 1 high torque tool or battery tools and torque wrenches.

* Connectivity to traceability servers using WiFi

* MSqnet production and quality software for guided assembly and preload analysis.

* Customizable torque toolset.

* Supports accessories such as scanners, printers, and other devices that use COM ports.

* Compatibility with multi-brand tools that use Open Protocol.

Conceived and designed for production activities outside of workstations, with mobility characteristics for areas of:

– Rework (outside the assembly lines), in the yard for assembly of missing parts or correction of assembly failures.

– Production in product batches.

– Work as a backup tool in the production line, in case of failure in the main tool.

– Training station for new employees or products.

– Try-out station or pre-series of new products to monitor the assemblies by the Engineering and Quality teams.

Functions

Rework station: the mobility and customizable functionality of the bench equipment allows the creation of several possibilities for assembling products in the yard in cases of lack of parts and also at the final check out of the line, enabling corrections that can respond to traceability systems, if any.

Batch production: allows the adjustment of tools to produce batches of products with quality and traceability, following specific production sequences.

Mobile or pre-production production station: Very useful in try-out processes of new products or in the adaptation of new workstations, where the necessary tests can be carried out without impacting the activities of the production line.

Training station: meets the learning needs to take on production jobs without impacting the quality of the products with basic errors and rework due to lack of product knowledge.

Backup station: being able to quickly replace equipment in malfunction until the station is repaired and restored by the maintenance team, minimizing production losses.

It uses Open Protocol for communication with multi-brand tools.

Ability to work with multiple tools in parallel.

Barcode scanner to scan the VIN of the production part.

Management of the various production models with customized procedures for each model and variant.

Reports and statistics.

Error management.

Local database or, in the case of more stations, centralized.

AC/DC power supply, with PC backup unit.

Basic Computer Config.

* All-in-One Industrial PC with 15″ Display,

* Windows® operating system,

* 10/100 Mbps network communication,

* Standard communication ports (USB, RS232, etc.),

* WiFi

* Optionally, it can be offered with a touch screen;

* Keyboard and mouse,

Software MSqnet QA

* Management of Users, Tools, Processes and Manufacturers;

* Generation of standardized PDF charts and reports

* Adaptable Organizational Structure;

* Statistical studies of outcomes with amplitudes, means, standard deviation, CP & CPK, +-3 sigma…

* Data export in CSV formats.

Software MSqnet STA

* It allows the creation of work management or software-guided assembly through an interactive screen, with the operator.

* Management, authorization and qualification of operator for the process in use.

* Controls the connected equipment for blocking and/or communication with the system.

* Allows you to obtain product assembly reports.

* Configurable I/O inputs and communication with external PLC.

* Issues alerts of incorrect or out-of-sequence assembly.

Preload Loss Software

* Manages collection points for control and monitoring.

* It allows the study of Preload through patented software with accuracy above 85%, when compared to expensive methods such as Ultrasound or joint instrumentation.

* It allows the creation of a database of the controlled points and historical mapping of the evolution of the product’s PDCA.

* Facilitates quality and product engineering studies.