Calibration

| Torque measuring instruments | Range (Nm) | Uncertainty |

|---|---|---|

| Torque Application Instruments | ||

| Nutrunner and/or Screwdriver | 1 Nm to 1272,9 Nm Angle: > 1º Method by comparison with a torque transducer Method by comparison with an angular displacement transducer | 0,12% 34´ |

| TORQUE MEASUREMENT INSTRUMENTS | ||

| Torque Wrench Calibrator | 1,1 N.m to 1272 Nm Method by comparison with a dead weight scale | 0,06% |

| Manual Torque Wrench Counterclockwise | 0,6 Nm to 1272 Nm Angle: > 1º Method by comparison with a dead weight scale Method by comparison with an angular displacement transducer | 0,06% 34´ |

| Manual Torque Wrench Clockwise | 0,6 Nm to 1272 Nm Angle: > 1º Method by comparison with a dead weight scale Method by comparison with an angular displacement transducer | 0,06% 34´ |

| Torque Transducer | 0,6 N.m to 1272 N.m Angle: > 1º Method by comparison with an angular displacement transducer | 0,06% 34´ |

| TORQUE APPLICATION INSTRUMENTS | ||

| Nutrunner and/or Screwdriver | >1 N.m to 1272,9 N.m Angle: > 1º Method by comparison with a torque transducer Method by comparison with an angular displacement transducer | 0,12% 34´ |

| Instrumentos de aplicação de torque | ||

|---|---|---|

| Apertadeira e/ou parafusadeira | 1 ~ 1272,9 | 0,12% |

| Instrumentos de aplicação de torque | ||

|---|---|---|

| Apertadeira e/ou parafusadeira | >1 ~ 1272,9 | 0,12% |

Realizados nas instalações do cliente

Calibration software

- Simplified processing of the information generated at the point of collection to the point of issue of the certificate, since the data is imputed online

- Lower cost of issuing the Certificate, avoiding expenses with printing standardized paper and RBC stamps

- Cost of envelopes, postage, transport to the post office, etc

- Optimization of client site that allows digital archiving of certificates

- Access to certificates via the internet/smartphone via login and password, with simplified search filters

-

Eases searching for documentation during audits with storage efficiency

-

Customers can view the certificate before issuing VALIDATION and give a Yes or No to approve according to their criteria

-

With greater agility, the certificate can be generated right after the end of the calibration, just by having Internet access at the workplace

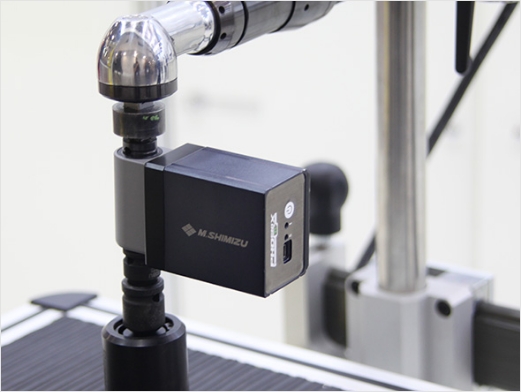

The first Brazilian rotary transducer

Developed with its own technology, it has a wireless system that makes it possible to send torque/angle data, generating statistics in real-time through the MSqnet QA software. Torque Transducers are supplied with an M. Shimizu calibration certificate.

MSRT models have torque reading only. The MSRTA models, in turn, have the ability to read the Angle. They count the number of readings to schedule preventive maintenance and equipment calibration.

Warns if the maximum torque reading capacity is exceeded (Overload Check). Includes battery charger. Its autonomy is up to 6 hours of continuous use.

Test Benches

Functions

- Tool testing: torque wrenches (analog, digital and snap), eletric, pneumatic and cordless nutrunners, Pulse Tools (except impact wrenches).

- Automatic detection of the click point of click torque wrenches.

- Statistical process control: Machine capability measurement (Cm, Cmk) and X and R charts.

- Test in accordance with ISO 6789 Reaction system for testing and calibrating torque wrenches.

- Database with tools archive, scheduling, and execution of tests and storage of results.

- Connectivity of external transducers for special tests.

- Clockwise and counterclockwise testing Mechanical joint simulators for testing nutrunners.

-

Statistics and reports Real-time curves on the monitor

-

Equipped with static torque transducers configured according to the tools to be tested on the production line.

-

Local or remote programming through management software for production line quality control.

-

Radio communication to external systems.

-

Database or local server

-

Torque accuracy less than 0.5% according to DIN 51309

-

Equipped with battery